My Contribution:

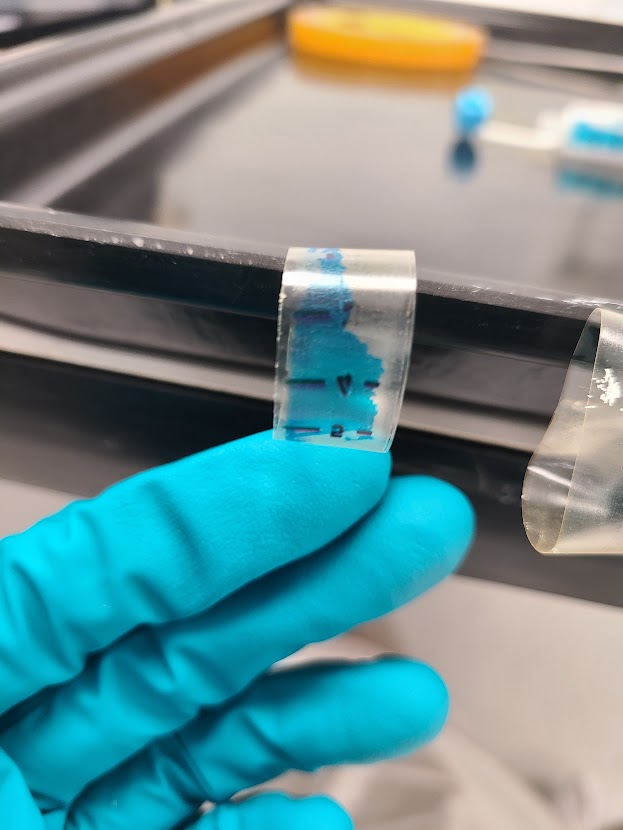

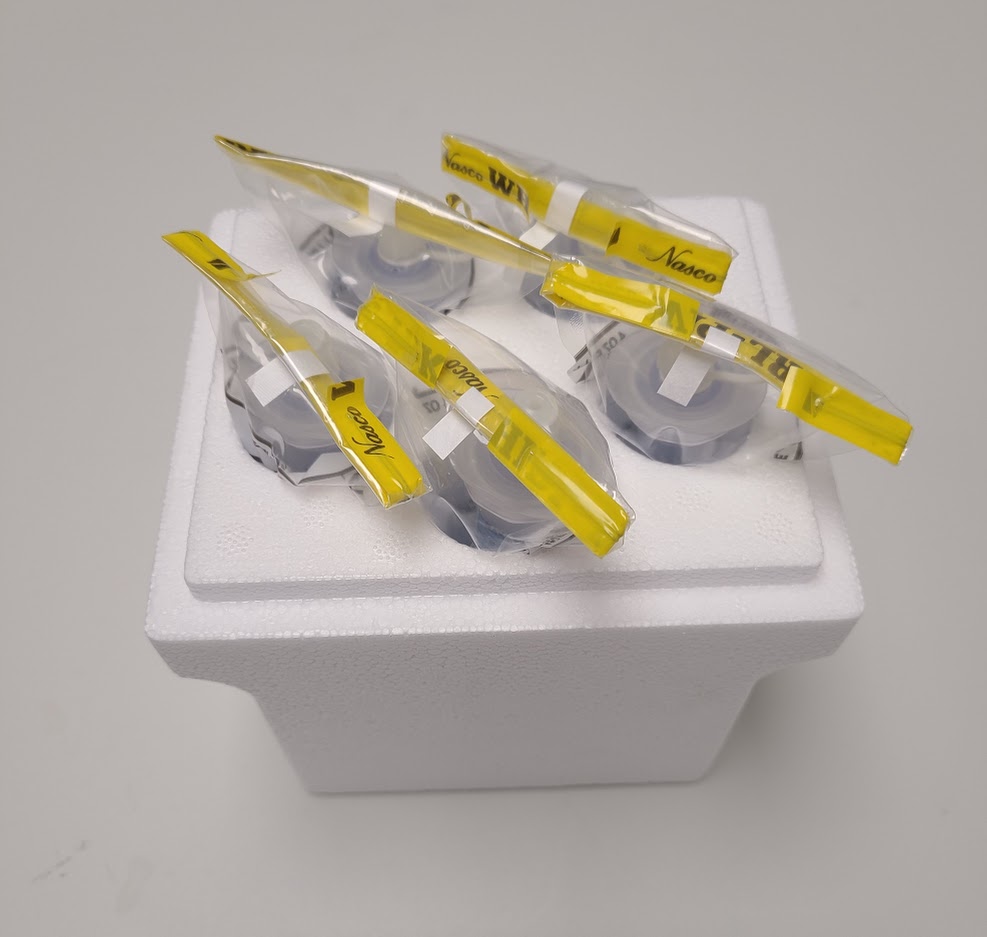

I inspected parts that we received from various manufacturers to ensure that they were compliant with our quality standards. Once all of the parts were inspected, I completed three different builds in a clean room for a total of 100 devices. We sent 60 devices to the client, and I performed engineering verification testing on the remaining devices. Some tests that I performed were drop testing, leak testing, ink adhesion testing, torque testing, and volume testing. For tests that did not pass, I worked with my supervisor to conduct root cause analysis, and took appropriate actions to ensure future devices would not fail. After the testing was complete, I wrote several reports about my findings and confirmed that the project was ready to move into formal verification and validation testing.